Project in Brief

- Project Name: Temecula Valley Regional Wastewater Reclamation Facility

- Location: Temecula, CA

- Installation Date: August 2024

- Source of Odors: 40 ppm of H2S Wastewater treatment processes

- System Type: Biofilter

- Media Type: Enhanced Cell-Max™, Crater-Max®

- Airflow: 10,750 cfm per biofilter cell

- Biofilter Size: 60′-0″ × 60′-0″ – Two (2) cells containing 10,800 cubic feet of media. 21,600 cubic feet of Enhanced Cell-Max™ installed

- H2S Removal Efficiency: >99%, with an average removal rate of 99.98% across two biofilter cells

The Situation

The wood chip media in Temecula Valley Regional Wastewater Reclamation Facility’s (TVRWRF) two biofilter media beds had been spent and was no longer providing sufficient odor control. Inlet concentrations of the foul air, from the treated wastewater processes, were tested and shown to contain as much as 40 ppm of hydrogen sulfide. TVRWRF’s odor control biofiltration system required an upgrade in their biofilter media to achieve a new benchmark in high-efficiency H2S mitigation.

The Solution

The project involved a comprehensive media replacement in two biofilter cells, where the spent GES wood chip media was exchanged for the Enhanced Cell-Max™ media. Engineered to enhance microbial colonization, the media delivers superior long-term performance, facilitating a consistently high hydrogen sulfide (H2S) removal efficiency.

Additionally, GES Biotek’s Crater-Max® media was introduced as an advanced air distribution substrate, optimizing air diffusion, and promoting ideal microbial conditions for H2S degradation.

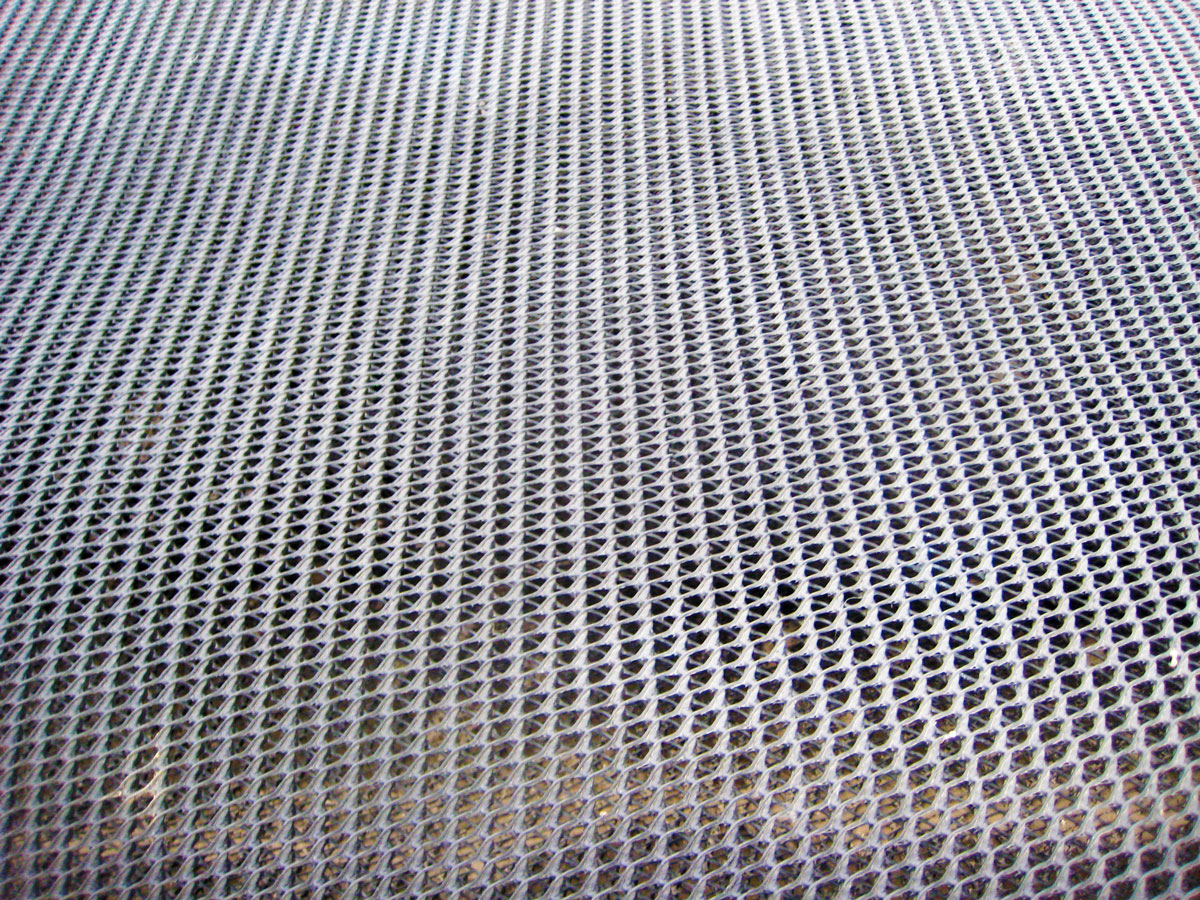

A high-density polyethylene (HDPE) Geonet Barrier Screen was installed to maintain separation between the Crater-Max® diffuser layer and the biofilter media. This component enhances structural integrity while ensuring efficient airflow and preventing particle migration within the biofilter system.

GES Super Nutrients were introduced into the biofilter via humidification nozzles at the system’s inlet, optimizing microbial activity by supplying essential growth factors, which further boosted H2S degradation performance.

Smoke testing was performed post-installation to assess the efficacy of the air distribution system, ensuring uniform air permeation across both biofilter cells. This process is crucial for ensuring consistent odor control across the entire biofilter system.

Post-installation testing confirmed that the biofilter system achieved an average H2S removal efficiency of 99.98%, reducing inlet concentrations of 40 ppm H2S to non-detectable levels. This exceptional removal rate ensures compliance with regulatory requirements and significantly improves the air quality surrounding the facility, minimizing odor impact on the local community.

With the completion of this project, GES Biotek reinforces its leadership in the development of innovative biofiltration technologies, providing high-performance solutions for odor management in wastewater treatment applications. The success of the Temecula installation paves the way for broader adoption of GES Biotek’s cutting-edge solutions worldwide.

Additional Case Studies

Eastern Municipal Water District, San Jacinto, CA

Enhanced Cell-Max™, Crater-Max®

GES Biotek installed a dual-media ecosystem to properly distribute the foul air and remove all complex odors and VOCs.

Woodlands Pump Station, Cary, NC

Enhanced Cell-Max™

GES Biotek manufactures engineered nutrient-rich open-cell substrate from recycled glass material that would otherwise end up in a landfill.

Hono’uli’uli WWTP, Honolulu, HI

Enhanced Cell-Max™

Three biofilters required outfitting with a complete odor control system, including all media, equipment and accessories.